How Build Angle Affects the Accuracy of 3D Printed Hybrid Ceramic Crowns and Veneers

As digital dentistry evolves, additive manufacturing (AM) is playing an increasingly pivotal role in the development of permanent dental restorations. A recent in vitro study published in the Journal of Dentistry by Alexey Unkovskiy’s team offers valuable insights into how build orientation affects the dimensional accuracy of 3D printed hybrid resin-ceramic restorations such as crowns, onlays, and veneers.

Understanding the Role of Build Angle in 3D Printed Ceramics

While 3D printing is already widely used for temporary dental components like splints, denture bases, and surgical guides, there remains limited clinical data on the dimensional accuracy of permanent restorations. This study aimed to address this gap by analyzing the effect of build orientation on the authenticity (trueness) and precision of printed hybrid resin-ceramic restorations using a DLP 3D printer.

Study Overview: Testing Five Build Angles

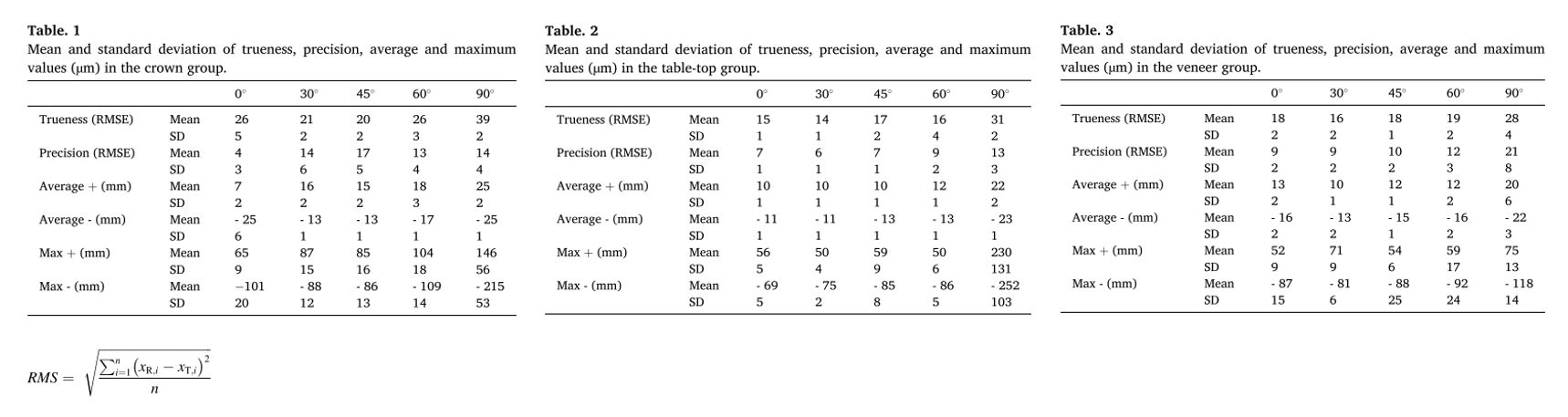

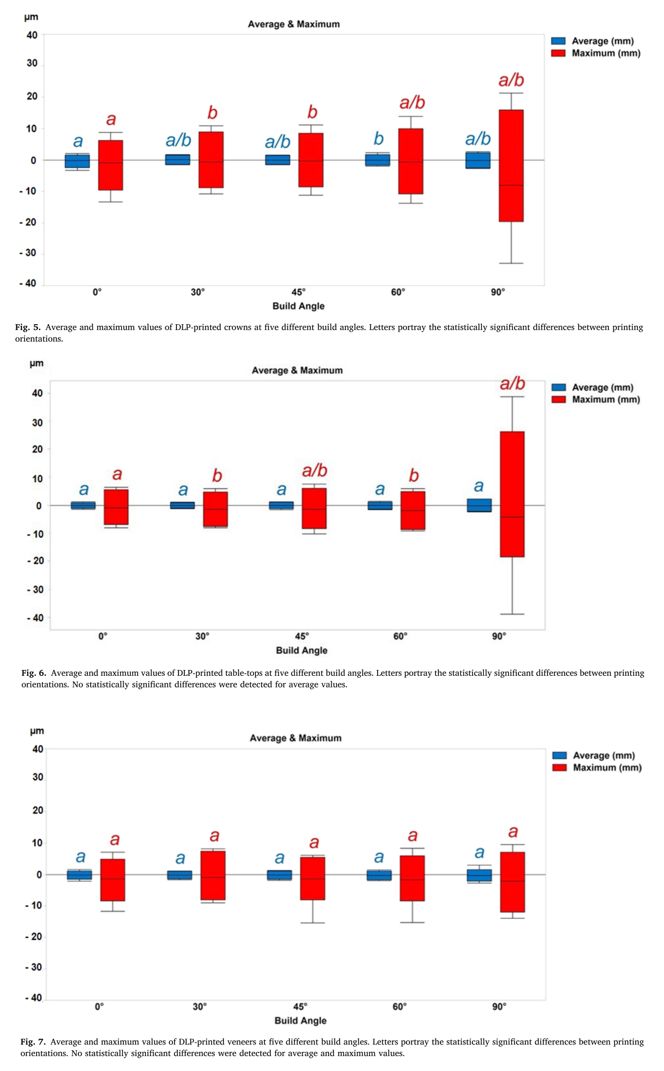

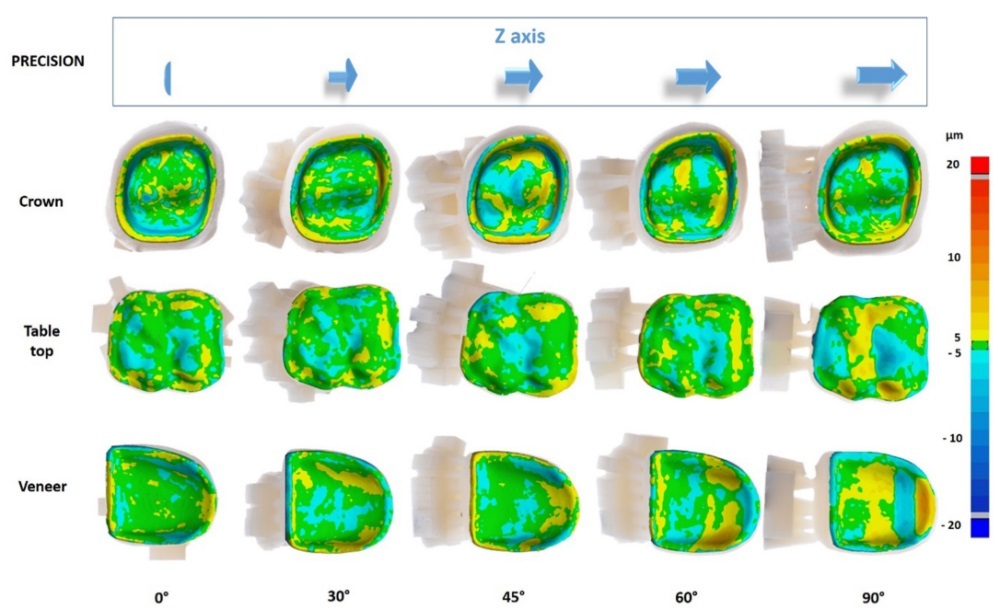

Researchers printed crowns, onlays, and veneers at five different build orientations—0°, 30°, 45°, 60°, and 90°—and evaluated the resulting dimensional accuracy. The outcomes were measured using quantitative deviation values and color maps indicating areas of concavity and convexity.

- 0°: Printing flat on the build platform

- 30° & 45°: Angled to improve support structure distribution

- 60° & 90°: More vertical orientations, often with increased support requirements

Key Findings from the Study

✅ Best Accuracy and Authenticity at 30° and 45°

The study found that a 30° angle produced the most accurate and authentic crowns and onlays. For veneers, all build angles performed acceptably except for 90°, which exhibited the lowest accuracy. This suggests that a moderate tilt during printing helps minimize print-induced distortions and improves fit.

⚠️ 90° Orientation Decreases Fit Quality

Across all restoration types, the 90° build angle was associated with the highest dimensional error. The errors were particularly concentrated along the crown walls and occlusal surfaces, areas critical to prosthesis retention and patient comfort.

🎯 Color Mapping Highlights Critical Fit Zones

Color maps visualized deviations in microns (±0.2 mm range). Yellow-red tones indicated overbuilding (convexity), while blue tones represented underbuilding (concavity). These visual tools help designers and clinicians pinpoint the most distortion-prone regions during the 3D printing process.

Why This Matters for Ceramic 3D Printing in Dentistry

Dimensional accuracy directly influences the clinical success of restorations. Poor fit leads to increased chairside adjustments, patient discomfort, or long-term failure. This study highlights the importance of optimizing build angle—a relatively simple yet powerful design parameter—to maximize the clinical viability of ceramic-based 3D printed dental components.

At AdventureTech, we’ve integrated these research findings into our ceramic 3D printing workflow. Our proprietary DLP ceramic 3D printers have been used to fabricate zirconia crowns and veneers with clinically reliable accuracy, especially when printed at recommended angles of 30° or 45°.

Final Thoughts

This study reaffirms that build orientation should not be treated as a secondary setting but as a critical determinant of 3D print success—particularly in precision-demanding fields like dentistry. Whether printing in hybrid resin or full-ceramic, optimizing print parameters can significantly reduce post-processing and increase clinical acceptance.

As the field advances, manufacturers, clinicians, and researchers alike must continue refining the intersection of material science and print strategy. Ceramic 3D printing isn’t just about material choice—it’s about design intelligence.

📩 Need Reliable 3D Printed Ceramic Restorations?

We offer professional ceramic 3D printing services using high-resolution DLP systems, including verified printing angles for dental restorations. Contact our team to discuss trial prints or custom development for crowns, veneers, or biomedical ceramics.

📧 Email: adventuretech@adt-ceramic3dp.com

🌐 Website: https://adt-ceramic3dp.com

More articles

Request A quote