DLP Ceramic 3D Printing of Glass Aspheric Lenses with Nanoparticle Slurry

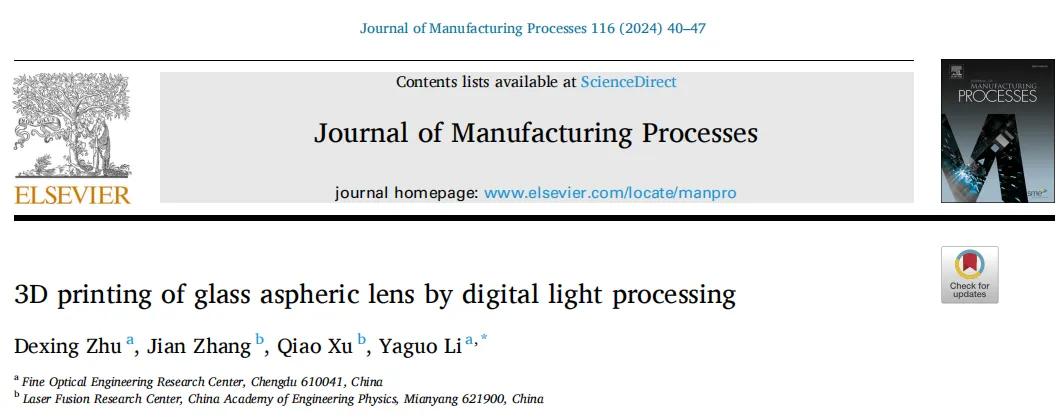

A recent study led by Yaguo Li from the Precision Optical Engineering Research Center has demonstrated a significant breakthrough in the additive manufacturing of optical components. Published in the Journal of Manufacturing Processes, the research explores the fabrication of centimeter-scale glass aspheric lenses via Digital Light Processing (DLP) technology, using UV-curable resin and silica nanoparticle slurry.

Background: Why Print Glass Optics?

Fused silica glass is widely valued for its optical clarity, thermal resistance, and chemical stability. However, its brittleness and low fracture toughness make it notoriously hard to process using traditional subtractive methods. Techniques like polishing, PGM, or chemical etching are costly and slow. While various 3D printing methods like FDM, TPP, and SLA have emerged, they are still challenged by slow print speeds and poor surface uniformity.

DLP-based glass printing offers new promise due to its high resolution and geometric freedom. However, previous attempts have struggled to scale up beyond micro-optics or overcome the layered appearance of prints.

Methodology Overview

This study presents a DLP-driven printing method using a UV-curable glass paste composed of silica nanoparticles and organic resin. Post-print processing includes:

Spin coating to smooth surface irregularities

Post-curing for layer cohesion

Degreasing and sintering to convert polymer parts into transparent glass

Material Rheology and Optimization

Viscosity was carefully characterized using parallel plate rheometry. At micron-level gaps (10–50 µm), shear-thinning behavior was observed. Optimizing this behavior allowed smoother deposition and minimized defects.

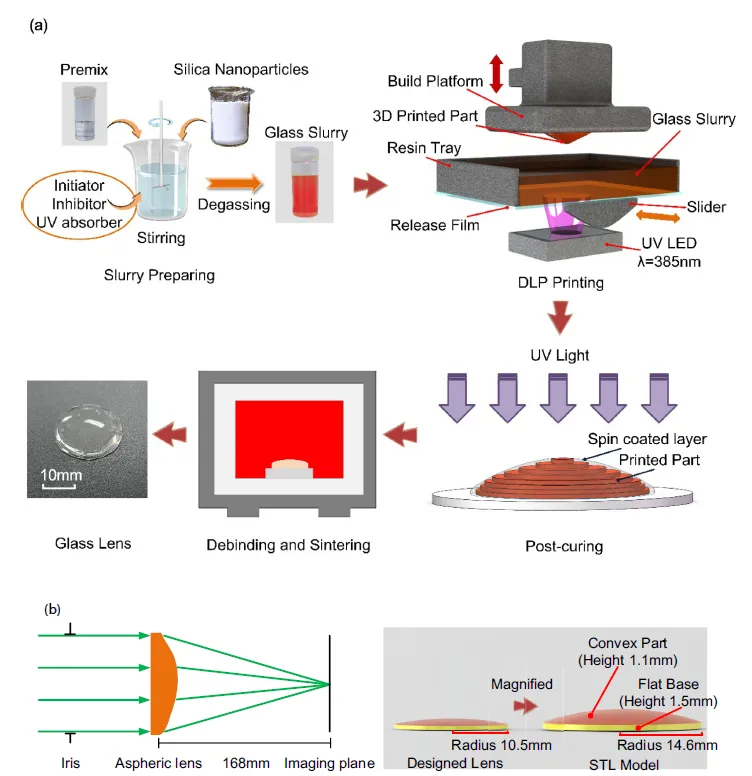

SEM of Aerosil OX50 confirmed uniform nanoparticle distribution

XRD analysis showed no crystalline peaks, indicating amorphous glass structure after sintering

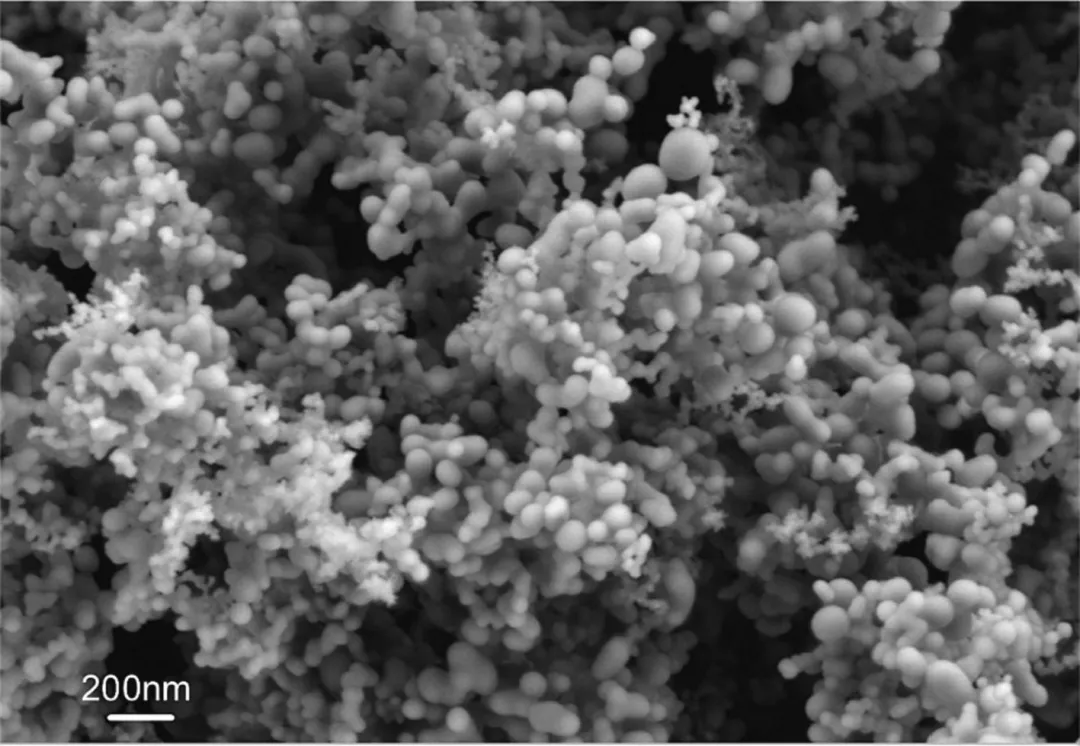

Surface roughness achieved: 14–15 nm RMS

Printed form deviation: Max deviation was 170 µm from design geometry

Imaging Resolution and Optical Performance

An imaging test revealed that:

Reference lens resolution: 90.5 lp/mm

3D printed lens resolution: 45.3 lp/mm

While this is lower than conventional optics, it is notable for a printed glass lens of this scale.

Conclusion and Industry Implication

This study validates a promising workflow for DLP-based 3D printing of centimeter-scale glass aspheric lenses using a silica nanoparticle slurry. The combination of DLP and post-curing not only addresses the challenges of layered structure but also enables smooth, transparent optical components with surface RMS under 15 nm.

However, current limitations include resolution (45.3 lp/mm) and shrinkage management during sintering. Further refinement in material loading and thermal profiling may unlock higher precision and broader commercial applications.

📩 Need Reliable 3D Printed Ceramic Restorations?

We offer professional ceramic 3D printing services using high-resolution DLP systems, including verified printing angles for dental restorations. Contact our team to discuss trial prints or custom development for crowns, veneers, or biomedical ceramics.

📧 Email: adventuretech@adt-ceramic3dp.com

🌐 Website: https://adt-ceramic3dp.com

More articles

Request A quote